Project Demo

Watch the robotic arm execute precision movements and calculate real-time inverse kinematics. Simulated in Webots and mirrored on physical hardware.

Overview

This project showcases a 4-DOF robotic arm I designed on SolidWorks from scratch, 3D printed for precision control and enacted with real-time simulation. Built using Arduino and simulated in Webots, it demonstrates inverse kinematics, servo coordination, and modular design principles (DFM). I used FEA static simulations on SolidWorks to amended the gripper design for less deformation under load.

Technical Highlights

- Inverse kinematics solver for smooth joint articulation

- Real-time sensor integration via serial communication

- FEA static simulations to amend design

- Webots + ROS2 coupled simulation synced with physical hardware

- DFM optimized linkages

Exploded View

Visual breakdown of the arm’s mechanical components and servo placements. Designed for easy assembly, maintenance, and part replacement.

FEA Optimization

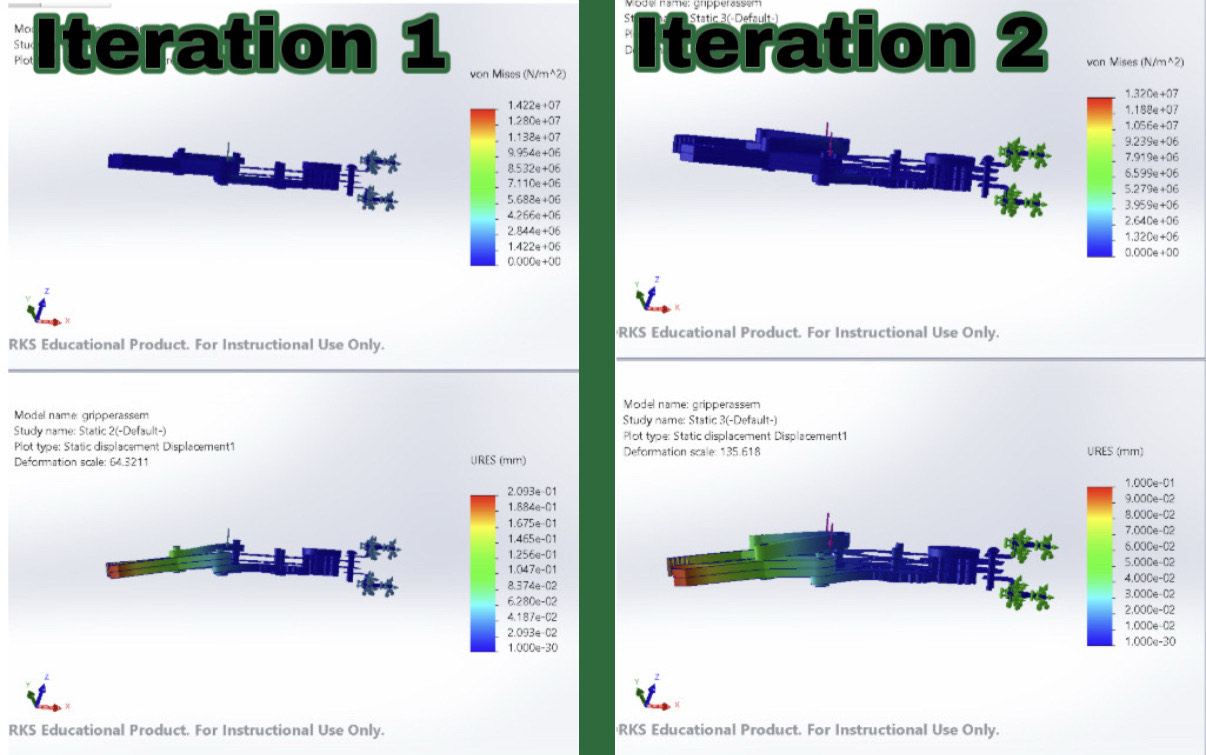

Comparative FEA results showing reduced stress and displacement after redesigning the gripper for a 100g tip load.

Adaptive Redesign of Gripper Assembly for Precision Load Handling

To optimize performance under a 100g tip load, I conducted a comparative FEA study on the gripper assembly. The original design showed stress concentrations up to 14.22 N/m^2 and tip displacements of 0.209 mm. Through iterative structural refinements, targeting geometry, material distribution, and load paths, I reduced stress to 13.20 N/m^2 and displacement to just 0.100 mm.

This redesign improved mechanical resilience as well as enhanced positional accuracy, which is critical for precision robotics.